|

Customer: Sydney Water Contract: Alliance Location: Sydney, New South Wales |

Fast Facts

|

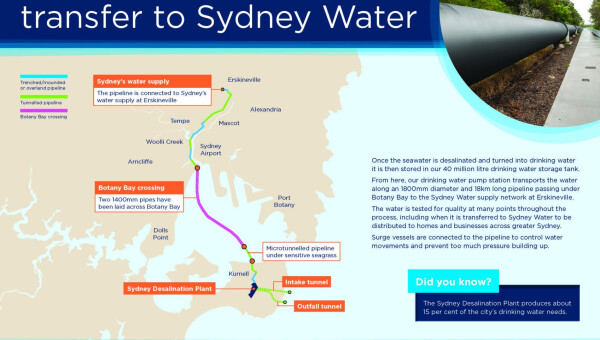

In partnership with Sydney Water and others, we formed the Water Delivery Alliance and designed and delivered the new pipeline and pump station linking Sydney's new desalination plant at Kurnell to the city's water network at Erskineville.

While the desalination plant was delivered via a conventional lump-sum contract, Sydney Water selected an alliance for the pipeline due to the technical, community and environmental risks involved.

The 17 km long pipeline, designed to carry 500 ML/day, includes 7.5 km of twin 1400 mm diameter steel pipelines across Botany Bay. The subsea crossing was the most challenging aspect of the project, requiring the Alliance team to develop some world firsts to ensure safe, on time and on budget delivery.

The balance of the pipeline included micro-tunnelling of 6.4 km of 1800 mm diameter steel pipe installed inside 2100 mm diameter concrete pipes, and approximately 3 km of 1800 mm diameter steel pipeline installed by conventional dig and lay trenching methods.

Nineteen shafts were constructed along the onshore portions of the pipeline, each location selected to minimise disruption to traffic and the community.

Technical Challenges and Innovations

The volume of water to be transported meant a single pipeline solution for the Botany Bay crossing would push engineering to its limits. Therefore a lower risk, twin pipeline solution was adopted by the team. Strict environmental controls meant the pipes had to be laid concurrently to minimise the impact of seabed disturbance. After extensive optioneering and risk assessment, a lay-barge solution was selected as the optimum installation method.

However, as there was no existing lay-barge capable of handling twin 1400 mm diameter pipes, the Alliance had to design and build its own. Working to a fast-track program, a standard flat-top barge was purchased, redesigned, fitted out and commissioned within 12 months. Transported from Malaysia via heavylift ship, the purpose-built barge enabled the team to successfully deliver the largest diameter twin pipelines ever installed by this methodology. Another technical challenge was the underwater recovery of the tunnel boring machine used for pipejacking the pipeline under sensitive seagrasses. The 110 tonne machine was successfully extracted, floated to shore, recovered and reused.

Stakeholder & Community Consultation

The Alliance was responsible for the development and roll-out of the stakeholder/community engagement program which was extensive due to the project's high profile and inner urban location. The program included:

-

generating the community and stakeholder management plan and associated protocols, procedures and documentation;

-

generating community information materials for flyers, website and public meetings;

-

establishing and maintaining relationships with local authorities, residents groups and other NGOs along the route;

-

liaison with landowners regarding access and worksite arrangements and easements;

-

providing regular briefings to councils, mayors and MPs along the route and responding to Ministerial enquiries;

-

undertaking 'door knocking' programs to advise the community of works proceeding;

-

responding to community and stakeholder enquires received in the field or by mail/electronic media;

-

generating and delivering Health, Safety, Environment and Community 'on boarding' induction program for all staff;

-

consultation on route changes.

The project was well received by the public through the efforts by the alliance team to develop construction methods that minimised impacts on the community and traffic.

Environmental Management

The team was responsible for obtaining all project environmental approvals and licences. The project team was highly tuned to developing methods and techniques aimed at avoiding destruction of sensitive seagrass areas at the bay shoreline. They developed a tunnelled solution – microtunnelling in sands underneath the seagrass at Silver Beach to 800 m offshore – a solution not deemed possible by the client during the early concept phase.

Project Outcomes

The Alliance demonstrated a strong partnership between the public and private sector and this highly technical project was successfully completed on time. The project won the NSW Government Partnership Excellence Award which recognises innovation in the development and delivery of public policy objectives. Judges looked at the scale, size and complexity of policy objectives, how risk was allocated, and achievement of time, cost and quality objectives.

The project has also received the Civil Contractors Federation Earth Award and was a finalist in the National Infrastructure Awards.