|

Customer: Auckland International Airport Ltd Contract type: Various Location: Auckland, New Zealand |

Fast Facts

|

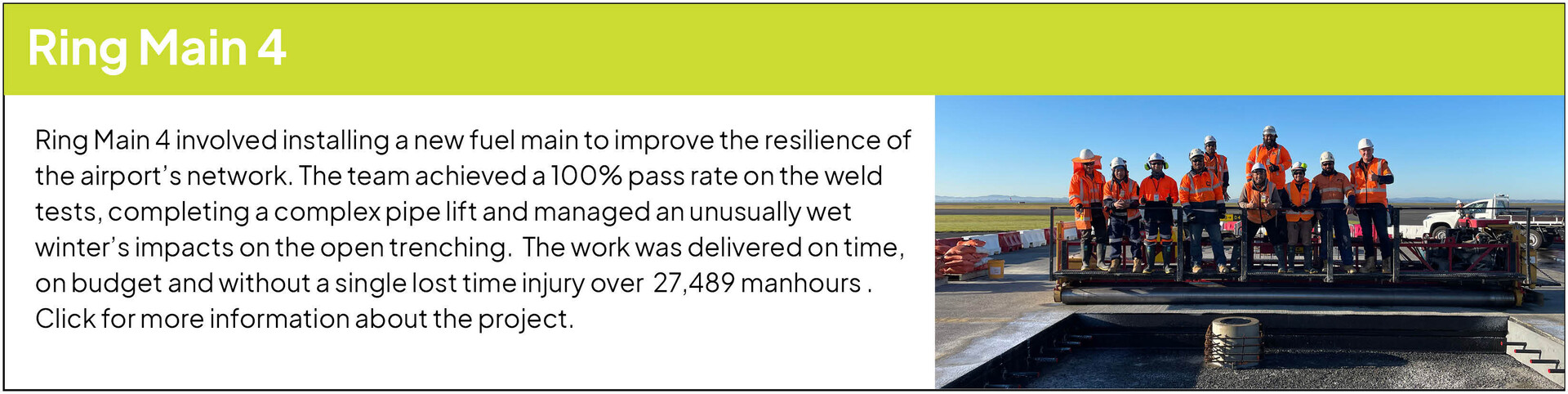

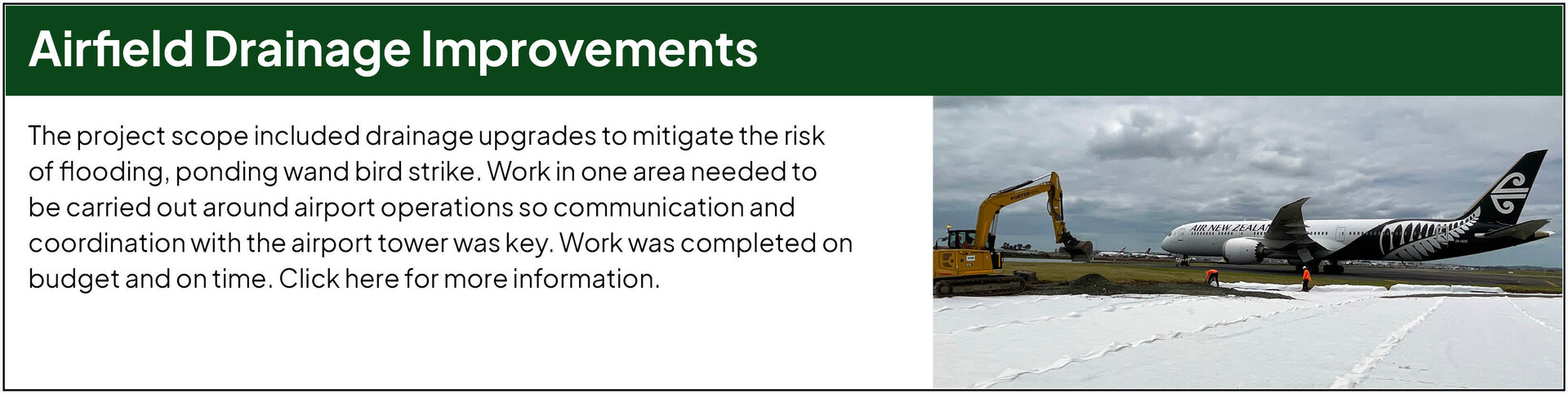

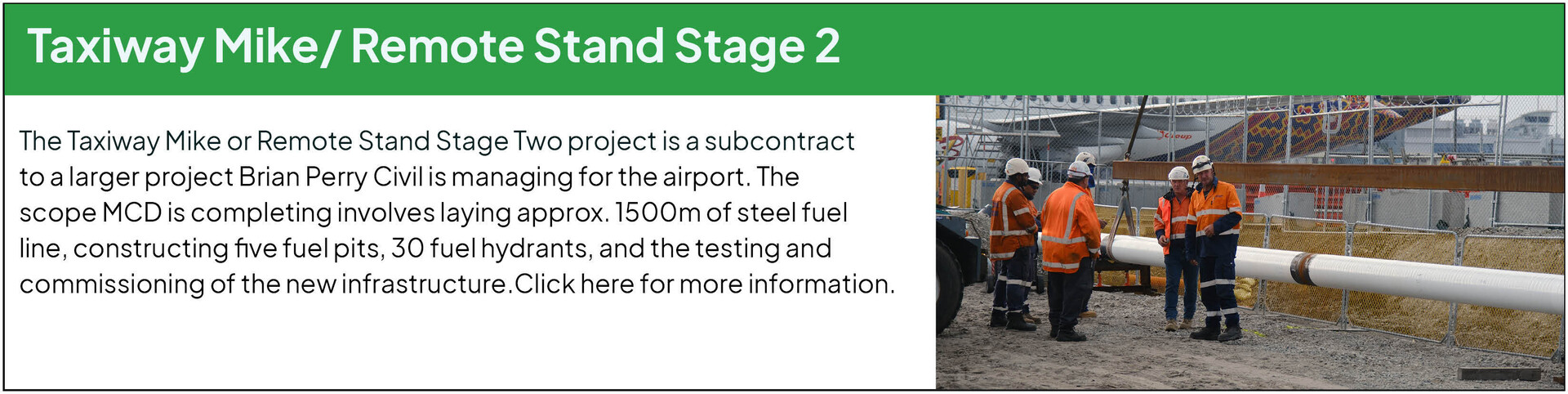

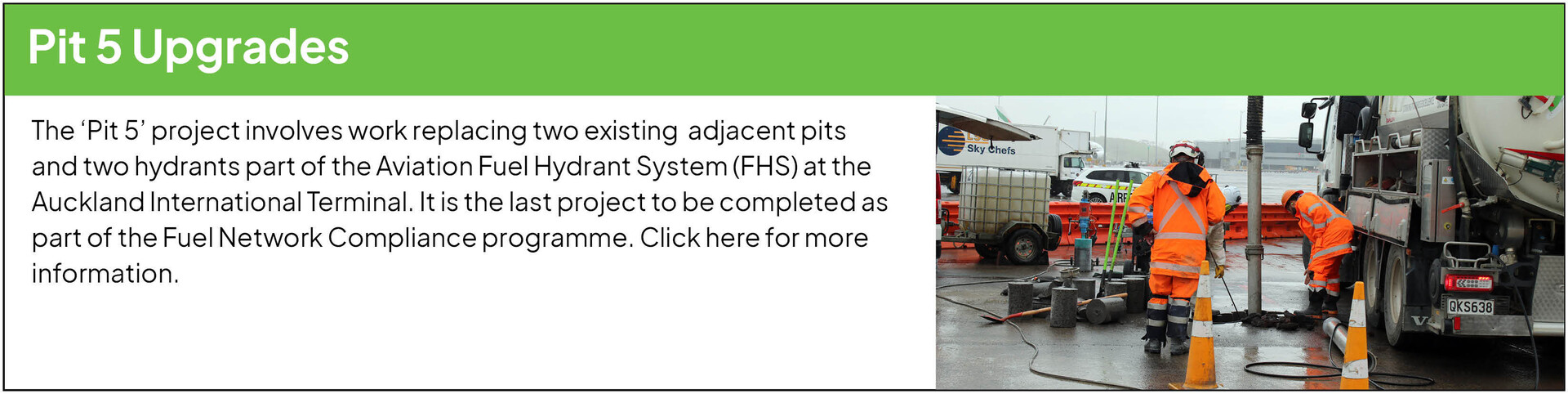

We've been working with the Auckland International Airport team since January 2019 to maintain and improve critical assets, including upgrading live jet fuel pipelines, renewing runway pavements, and much more.

We have also worked on vertical construction projects, including the new airport upgrade with subsidiary Built Environs.

We have installed fuel pipelines and utilities underground, relocated secure facilities, and built new roads and pavements - civil, mechanical, fabrication, pipelines, and vertical construction - we can do it all.

The projects listed below demonstrate our flexibility and responsiveness to our clients’ needs. Simply click on each project to learn more.

The projects we have completed at the airport over the last six years include...

Click on the boxes below to expand (and hide) them for more information about the projects, including detailed scope and delivery.