|

Customer: Fultoin Hogan Contract: Fabrication, installation & removal Location: Pakuranga, East Auckland |

Fast Facts:

|

We fabricated, installed and removed the temporary steel structures that helped make the launch of the new AMETI bridge sections a success for Fulton Hogan.

"Only a complete team effort has made launching this bridge across the Tāmaki Bridge possible. Thanks to Ryan and the MCD team for the fabrication and installation of all the tricky temporary works," Jeremy Gordon, Bridge Manager, AMETI.

The scope of work for this project required precision fabrication, complex rigging over water, and close coordination with other contractors during delivery. The 60-tonne custom steel structure was fabricated at our Manukau facility, installed onsite by our team and was a critical component of the successful staged launch of the bridge sections. In addition, we were required to modify some launch gear supplied by the client from a previous project to suit the winching systems and foundation details of the new bridge.

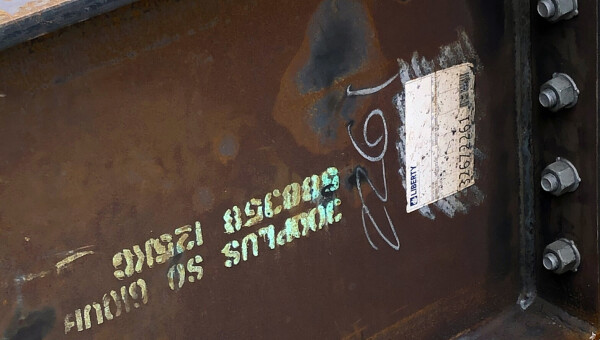

The team fabricated the support frame from 610UB125 universal beams and 310UC97 columns. Skilled welders then completed full-strength butt welds in tight spaces and challenging conditions, meeting the highest levels of quality assurance.

These heavy steel members had to be lifted over water from scaffold platforms, which meant the team needed to design complex rigging systems and ensure precise coordination onsite to assemble the supports. One of the challenges was the installation's tight elevation tolerances to match the precision of the launch geometry. The temporary works structure was also erected in a tidal zone, so the team needed to carefully plan work around water levels to ensure the column legs were positioned accurately onto pile caps.

Once the temporary support frames were in place, the team maintained the structure throughout the bridge launch part of the project. When all the new bridge sections had been pushed out across the rollers onto the new piles and their final position, the team began removing the temporary works. The temporary works needed to be removed as the new bridge was lowered onto its permanent supports, so demobilisation was tightly sequenced and controlled.

Work on the project began in November 2019, and was completed in February 2021, made possible by clever temporary works and the onsite expertise of the Mechanical Division.